Plastic moulding company -

Injection moulding of plastics

We deal with moulding plastic parts and assembling larger assemblies for the automotive industry.

We deal with moulding plastic parts and assembling larger assemblies for the automotive industry.

We are an expert in injection moulding of plastics. We have state-of-the-art technologies including Engel injection moulding machines, which we always buy brand new, equipped with all the necessary accessories. This enables a stable and efficient process at the end of which are precise and high-quality products which satisfy even the most demanding customers from global car manufacturers.

We are able to supplement the main activity – injection moulding of plastic parts – by mounting metal or other components and subsequent completion into more complex assemblies.

We can also offer welding and subsequent painting in our sister company.

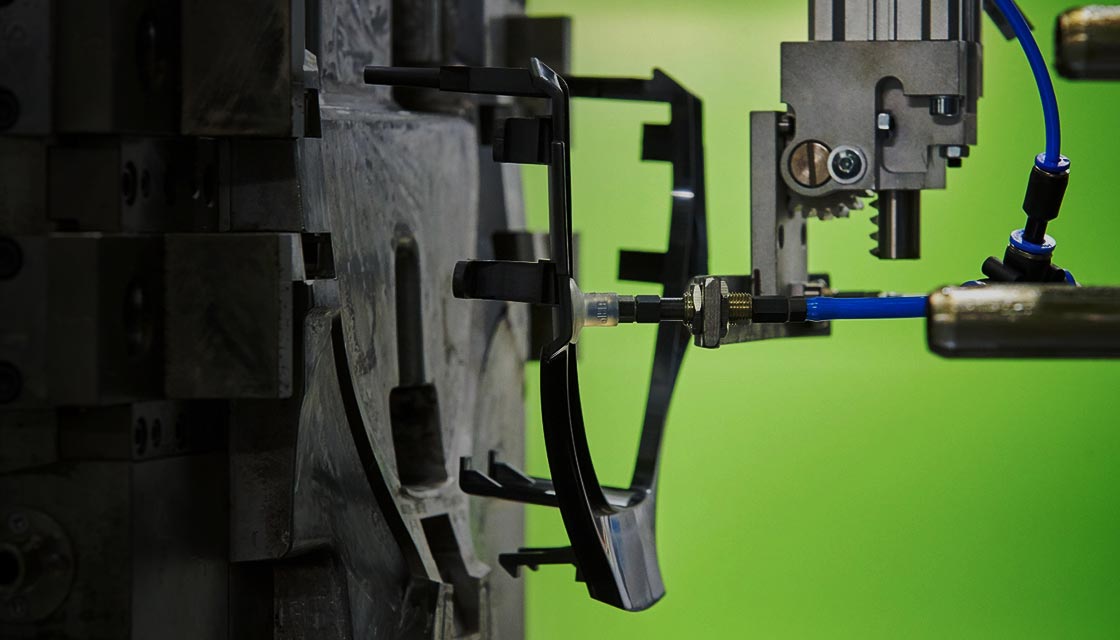

Plastic parts are made using the most modern column-free ENGEL injection moulding machines.

All the machines are equipped with linear robots and complete accessories which enable removal of the parts, cutting of the gate stems, optimum handing and heating of moulded parts, while standard plastics, such as PP, ABS, PC/ABS, and ASA, as well as materials with a high glass fibre content, can be processed.

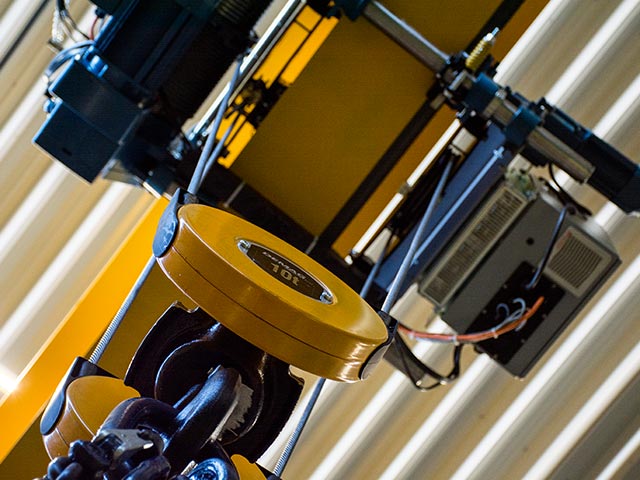

To handle the injection moulding tools, we use a professional 10-ton crane made by DEMAG.

Our team of qualified workers, together with modern technological equipment, is a guarantee of high quality and a stable production process of:

We currently own 7 injection moulding machines with the following closing forces:

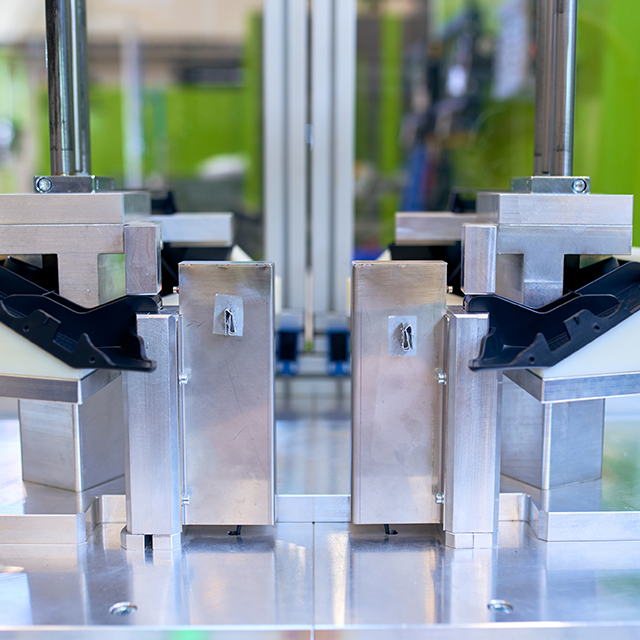

We do our best to offer each customer comprehensive services. Therefore, in addition to moulding plastic parts, we also provide assemblies of various extent. They include assemblies of metal components (clips, spindles) or applications, e.g., of double-sided bonding tapes.

Assemblies and completion of final products are performed using sophisticated single-purpose equipment which ensures the correct technological procedure.

Further services we can offer our customers include ultrasound welding and especially painting in our sister company, COLORPROFI s.r.o.

As our customers have very high quality requirements, we especially strive for a stable and effective production process which is subject to a properly set quality management system.

From the very beginning, we pay attention to the production material, which goes through a strict input inspection. Mass-produced parts are regularly checked visually within inter-operational inspections and measured according to the inspection documentation, which results in timely detection of defects and/or immediate introduction of corrective actions.

Our company is certified according to ISO 9001 and we further work on certification according to automotive standards. Customer-defined parameters are checked using Mitutoyo 3D measuring equipment with modern SW which enables part CAD data to be linked with the measuring device SW. When working with 3D data, we use the CATIA V5 CAD system .

Customer-defined parameters are checked using Mitutoyo 3D measuring equipment with modern SW which enables part CAD data to be linked with the measuring device SW. When working with 3D data, we use the CATIA V5 CAD system .We also own the following sophisticated software: